Branch logger for sale Urban HM70

The branch loggers URBAN produces large chips (logs) from branches and waste wood –blocks. Unlike fine chips, large chips (logs) are suitable for heating in conventional solid fuel boilers and wood gasifying boiler. You convert waste wood and branches into full fuel thanks to chipping. The branch loggers URBAN are working on the principle of two counter-rotating shafts with knives. The rotating blades draw in the wood material into the feed hopper unassisted.

Machine Description

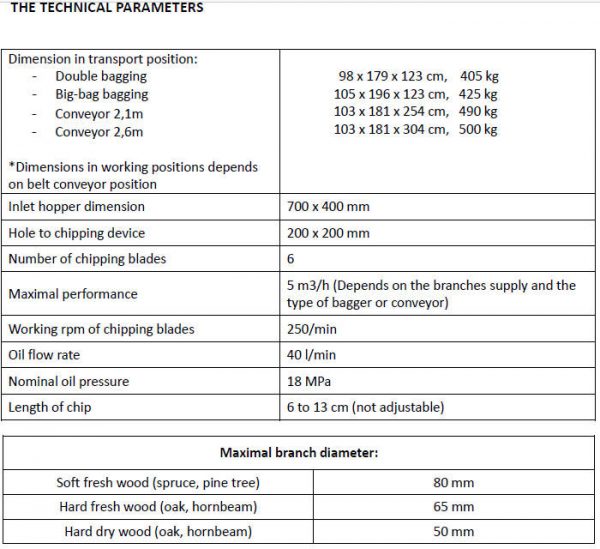

The branch logger URBAN HM70 is driven by a hydraulic motor. It processes material with a diameter of up to 8 cm, and the length of the resulting logs is 6 -13 cm. The source of hydraulic oil is the hydraulic power unit to which the machine is connected via the connecting frame and 2 hydraulic quick couplings. We produce various types of connecting frames, making it possible to attach a branch logger to a wide range of hydraulic power units such as skid steer loaders, farm manipulators, construction or communal machines. The connecting frame is not a part of the machine, it must be ordered as an accessory.

The connection to hydraulic power unit

The connection to hydraulic power unit

The machine is attached to the hydraulic power unit and its hydraulic circuit. Required parameters of the hydraulic circuit of the power means are oil flow rate min. 40 l/min (optimally 50 l / min or more) and oil pressure min. 18 MPa.

The machine is controlled by the hydraulic distributor lever and the flow regulator, which adjusts the speed of the chipping device.

The connecting frame

The connecting frame must be mounted on the device. It is supplied as an accessory. The connection frame is used to connect the device to the hydraulic power. We supply different types of connecting frames for different hydraulic power unit (EURO NORM, UNC 60, 3-point hitch, …). The 2 front sliding legs are part of the connecting frame, which serves to ensure the optimum working height during chipping (the other 2 rear sliding legs are part of the branch logger frame).

The inlet hopper

The inlet hopper consists of a fixed and a folding part. The folding part of the inlet hopper gives a narrower profile in the transport position. Once locked in the working position the hopper ensures optimised branch intake and operational safety. Additionally, the hopper is fitted with a safety cut-out frame, which by pressing down stops the chipping device. The inlet hopper is oriented horizontally, which greatly facilitates insertion of long branches compared to the vertical or sloping hopper. Surface treatment of the whole machine is made with powder paint.

The chipping device

The working principle of branch loggers URBAN lies in two counter-rotating shafts with knives. The rotating knives draw in the wood material into the feed hopper unassisted. The passage gap between the shafts is 70 mm. Each shaft has 3 fixed knives, made from high-quality tool steel. It is possible to re-sharpen the knives repeatedly. After sharpening there is a pad to be put under the knives in order to keep the same gap between the knives (c. 0,1 mm). One single sharpening of knives is capable of producing from 100 to 500 solid meters of small logs, depending on the level of contaminants (mud, nails, stones etc.). Each blade can be sharpened up about 4 mm, then it must be replaced with a new one.

The double bagging for raschle bags

It is used raschle bags of 57 × 104 cm. The flap can be switched between filling one or the other bag. After filling the first bag, there is no need to interrupt the job due to a full bag -just flip the flap and the chips fall further into the second empty bag. During the filling of the second bag, it is possible to replace the first, already full bag. Continuous insertion of the branches allows filling bag in 20 seconds. Optimal for the operator of the machineare2-3 persons, one of them only changing the bags. We provide 50 pcs of raschle bags free of charge with each machine.

It is used raschle bags of 57 × 104 cm. The flap can be switched between filling one or the other bag. After filling the first bag, there is no need to interrupt the job due to a full bag -just flip the flap and the chips fall further into the second empty bag. During the filling of the second bag, it is possible to replace the first, already full bag. Continuous insertion of the branches allows filling bag in 20 seconds. Optimal for the operator of the machineare2-3 persons, one of them only changing the bags. We provide 50 pcs of raschle bags free of charge with each machine.

The belt conveyor

The conveyor with length 2,1 m or 2,6 m is driven by V-belt drive. The slope of the conveyor is adjustable by means of a winch. The conveyor is lifted to a vertical position during transport. As an optional accessory, it is possible to mount a double bagging device with a support leg at the end of the conveyor. The bag is secured by four screws and it takes only a few minutes to fit it.

The Big-Bag bagging device

It is used aerated large-size bags of 90 x 90 x 100 cm. The Big-Bag using is faster because bags do not have to be changed so often compared to smaller raschle bags. The Big-Bag (also full) could be lifted by power unit’s hydraulics during moving in the forest. The adjustable arms of bagging device are retractable.

It is used aerated large-size bags of 90 x 90 x 100 cm. The Big-Bag using is faster because bags do not have to be changed so often compared to smaller raschle bags. The Big-Bag (also full) could be lifted by power unit’s hydraulics during moving in the forest. The adjustable arms of bagging device are retractable.

Price List

HM 70 with double bagging €5,097.56 ex. vat €6,270.00 incl. 23% vat

HM 70 with Big Bag bagging €5,097.56 ex. vat €6,027.00 incl. 23% vat

HM 70 with conveyor 2.1m €6,402.44 ex. vat €7,875.00 incl. 23% vat

HM 70 with conveyor 2.6m €6,699.19 ex. vat €8,240.00 incl. 23% vat

HM 70 with folding belt conveyor 3.4 m

€7,300.81 ex. vat €8980.00 incl. 23% vat

Options

Connecting Frame EURO NORM €395.00 ex. vat €485.85 inc. vat

Connecting Frame UNC 60 €395.00 ex. vat €485.85 inc. vat

Connecting Frame 3-point hitch €340.00 ex. vat €418.20 inc. vat